Driers/Siccatives | ECOS & VALIREX

Discover our Wide Portfolio of Primary, Secondary and Auxiliary Paint Drying Additives

Building on years of research and development in partnership with the paints & coatings industry, we have developed a comprehensive portfolio of primary, secondary, and auxiliary paint drying agents. Our offerings include traditional products like primary cobalt driers, secondary zirconium driers and many more. Moreover, we have innovated beyond these traditional solutions with patented polymer technology and mix driers, including solutions for waterborne systems, also known as aquatic coatings.

Your formulation and application will determine the right composition of paint drying systems for optimal drying properties. Choosing the wrong siccative can lead to issues like wrinkling, cracking, and discoloration in the coating.

The Paint Drying Process – Is Paint Drying a Chemical Reaction?

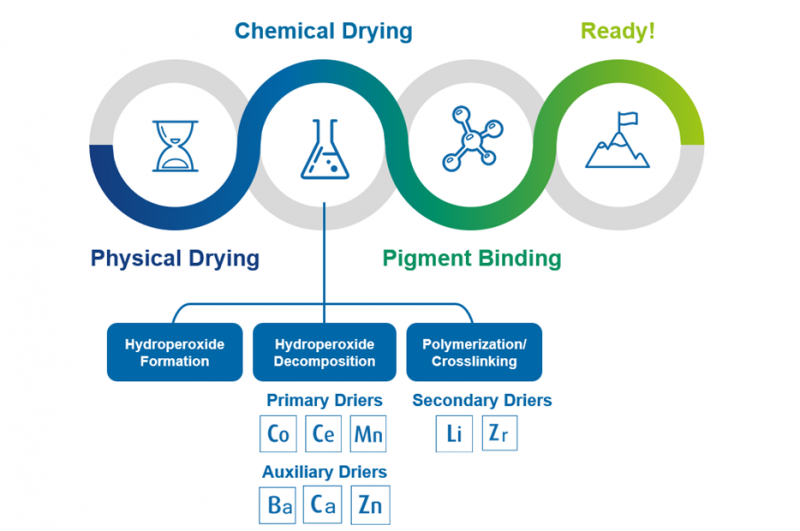

Alkyd paint drying is a complex, multi-step process with several critical phases. When asked, "Is paint drying a chemical reaction?" the answer is definitely "yes". Three distinct drying phases can be identified.

The first is physical drying, where the solvent evaporates and a closed film forms.

The second phase is chemical drying, an oxidative process where the binder compound is oxidated with oxygen from the air. This phase has three overlapping sub-stages: hydroperoxide formation, hydroperoxide decomposition into free radicals, and polymerization/cross-linking.

The third and final phase involves the cross-linked alkyd polymer network binding the pigment to the paint surface.

So, where do our drier chemicals come in? Primary driers, also known as surface driers or auto-oxidation catalysts, primarily ensure catalytic hydroperoxide decomposition. Auxiliary driers, which enhance the performance of primary driers, can prevent wrinkling and improve hardness, gloss, and drying performance. They also promote pigment wetting and reduce the adsorption of primary driers to the pigment. Lastly, secondary driers act as cross-linkers, ensuring overall drying throughout the coating.

Primary Driers/Siccatives – Manganese and Cobalt Polymer Technology

Regulatory developments cast doubt on the future use of traditional cobalt driers, like cobalt octoate, under question, especially in consumer applications like paints. Responding to this uncertainty, we have developed our patented ECOS portfolio. ECOS products incorporate metal in a polymeric structure, limiting its bio-accessibility. This ensures safety without compromising on drying performance.

Interested in reading more on our efforts to create safe, low-toxic chemicals with improved environmental impact? Read our information on the replacement of traditional cobalt products.

| ECOS MND 10 | Manganese polymer drier. One-to-one replacement for VALIREX Co 10 D60. |

|

| ECOS ND 15 3 D60 | Cobalt polymer drier with 3% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| ECOS ND 15 Aqua | Cobalt polymer drier with 3.5% metal content. Suitable for water-based applications. |

|

| ECOS ND 15 | Cobalt polymer drier with 4% metal content. | |

| ECOS ND 15 5 | Cobalt polymer drier with 5% metal content. Low-viscosity grade. |

|

| ECOS Mix Neo | Cobalt polymer mix driers with either/and barium, calcium, zirconium, zinc. Grades for water-based applications available (ECOS Mix Aqua). |

Primary Driers/Siccatives – Traditional Cobalt, Cerium, Manganese & Mix Portfolio

In addition to our innovative polymer technology, we continue to offer traditional VALIREX metal carboxylates. Within our cobalt, cerium, and manganese carboxylates range, we offer octoate-free grades to address toxicity concerns related to 2-ethylhexanoic acid and its metal salts.

Interested in reading more on our efforts to create safe, low-toxic chemicals with improved environmental impact? Read our information on octoate replacement.

Cobalt Driers

Cobalt carboxylates are the most effective oxidation catalysts at ambient temperatures. Cobalt driers produce fast surface drying to the film.

| VALIREX Co 6 D60 | Cobalt octoate drier with 6% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Co 6 LTD | Cobalt carboxylate drier with 6% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Co 9 Aqua | Cobalt neodecanoate drier with 9% metal content. Suitable for water-based applications. |

|

| VALIREX Co 10 D60 | Cobalt octoate drier with 10% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Co 10 Neo D60 | Cobalt neodecanoate drier with 10% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Co 12 D60 | Cobalt octoate drier with 12% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Co 18 BORO D60 | Cobalt boro-acylate drier with 18% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Cerium Driers

Cerium carboxylates promote polymerization and through-drying processes. They are particularly recommended for baking enamels and white and clear overprint varnishes, as they produce less discoloration than other active metals.

| Cerium neodecanoate drier with 8% metal content, diluted in a vegetable fatty acid ester. |

||

| Cerium neodecanoate drier with 10% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Manganese Driers

Manganese carboxylates do not only enhance the surface drying of the coating, but also have some through-drying properties. When combined with cobalt, balanced surface and through drying is achieved. However, due to their brown color, high concentrations of manganese driers are not ideal for use in light-colored or white paints. They typically perform well under elevated heat.

| VALIREX Mn 0.5 D60 | Manganese octoate drier with 0.5% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Mn 6 D60 | Manganese octoate drier with 6% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Mn 8 D40 | Manganese octoate drier with 8% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 40° C. |

|

| VALIREX Mn 8 Neo D60 | Manganese neodecanoate drier with 8% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Mn 8 Neo LV | Manganese neodecanoate drier with 8% metal content, diluted in a vegetable fatty acid ester. |

|

| VALIREX Mn 8 Neo Ester | Manganese neodecanoate drier with 8% metal content, diluted in a vegetable fatty acid ester. |

|

| VALIREX Mn 10 D60 | Manganese octoate drier with 10% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Mix Driers

Mix driers can boost efficiency while ensuring excellent and stable quality. Umicore provides a selection of different drier combinations, with properties depending on the metal types and concentrations involved.

| VALIREX Mix | Combination driers with either/and barium, calcium, cobalt, lithium, zirconium, zinc. Grades for water-based applications available (VALIREX Mix Aqua). |

Secondary Driers/Siccatives - Lithium & Zirconium Portfolio

Within our range of lithium and zirconium carboxylates, octoate-free grades are available to counter actual toxicity concerns related to the substance 2-ethylhexanoic acid and its metal salts.

Interested in reading more on our efforts to create safe, low-toxic chemicals with improved environmental impact? Read our information on octoate replacement.

Lithium Through Driers

Lithium carboxylates promote through-drying, making them popular in high-solid coatings and water-dispersible alkyds. They remain effective, even in cooler environments. Lithium driers enable surface hardening of alkyd resins. However, caution is needed to avoid overdosing as it can impact the films' weathering resistance.

| VALIREX Li 2 Neo D60 | Lithium neodecanoate drier with 2% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Zirconium Through Driers

Zirconium carboxylates enhance the through-dry of auto-oxidative drying systems and are most active on alkyd resins containing high levels of hydroxyl groups. They are often used in combination with cobalt and calcium carboxylates.

| VALIREX Zr 12 Aqua | Zirconium octoate drier with 12% metal content. Suitable for water-based applications. |

|

| VALIREX Zr 12 D60 | Zirconium octoate drier with 12% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zr 12 Neo PR D60 | Zirconium neodecanoate drier with 12% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zr 18 D60 | Zirconium octoate drier with 18% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zr 18 Neo PR D60 | Zirconium neodecanoate drier with 18% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zr 24 D60 | Zirconium octoate drier with 24% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Auxiliary Driers/Siccatives - Barium, Calcium & Zinc Portfolio

Within our range of barium, calcium and zinc carboxylates, octoate-free grades are available to counter actual toxicity concerns related to the substance 2-ethylhexanoic acid and its metal salts.

Interested in reading more on our efforts to create safe, low-toxic chemicals with improved environmental impact? Read our information on octoate replacement.

Barium Driers

Barium carboxylates improve through-drying of coatings and have good pigment wetting characteristics. They demonstrate lower water sensitivity than calcium carboxylates and reduce loss-of-dry.

| VALIREX Ba 12.5 D60 | Barium carboxylate drier with 12.5% metal content (octoate-free), diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Calcium Driers

Calcium carboxylates are popular driers and beneficial when used with active driers like cobalt and manganese. They improve hardness and gloss while reducing skin-formation, silking, and blooming. Additionally, they serve as pigment wetting/dispersing agents and loss-of-dry inhibitors. However, calcium carboxylates are not recommended for coatings that must dry under adverse conditions such as water sensitivity.

| VALIREX Ca 4 OB D60 | Calcium carboxylate drier with 4% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Ca 5 N D60 | Calcium octoate drier with 5% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Ca 5 N Neo D60 | Calcium neodecanoate drier with 5% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Ca 5 OB D60 | Calcium carboxylate drier with 5% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Ca 10 OB D60 | Calcium carboxylate drier with 10% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

Zinc Driers

Zinc carboxylates keep auto-oxidative films "open" by slowing down the cobalt drier, which allows hardening throughout the coating. They are highly effective as wetting/pigment-dispersing agents and carry the added benefit of inhibiting mildew formation in coatings and enhancing gloss levels.

| VALIREX Zn 8 D60 | Zinc octoate drier with 8% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zn 10 D60 | Zinc octoate drier with 10% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zn 12 D60 | Zinc octoate drier with 12% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zn 12 VER | Zinc carboxylate drier with 12% metal content. | |

| VALIREX Zn 16 Neo D60 | Zinc neodecanoate drier with 16% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zn 18 D60 | Zinc octoate drier with 18% metal content, diluted in a dearomatized hydrocarbon mixture with a flash point of 60° C. |

|

| VALIREX Zn 22 | Zinc octoate drier with 22% metal content. | |

| VALIREX Zn 22.5 | Zinc octoate drier with 22.5% metal content. |

Your experienced partner for Paint Drier solutions!

Get in touch with our experts.

If our product overview does not meet your needs, Umicore offers custom solutions tailored to your specific formulation or process. We differentiate ourselves through quality and our willingness to develop new products for specialty needs. As an experienced manufacturer of metal carboxylates, we are here to help you create the right product. Our R&D department would be pleased to assist with analyses and testing to meet your requirements. We also offer pilot plant capacity for a seamless scale-up of your custom drier.